A vacuum pump is a device that creates a partial vacuum or full vacuum by removing or eliminating gas from an enclosed, sealed space. Note that the vacuum pump is not the same thing as an air compressor, which increases gas by reducing its volume. Read More…

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

GlobalVac & Air was founded in 1994 and is a leading supplier and packager of medical, lab and industrial vacuum systems. We specialize in rotary dry claw, liquid ring, rotary vane and rotary screw technology. Call us today for innovative solutions to all of your pumping needs!

In business since 1950, Osaka Vacuum is a manufacturer of highly reliable vacuum systems, industrial vacuum pumps, and vacuum pumping systems. Products include dry vacuum pumps, roots vacuum pumps, turbo molecular pumps, rotary vane vacuum pumps, liquid-ring vacuum pumps, oil-sealed vacuum pumps and more. Our motto is "reliable, long lasting products that give you safety and satisfaction.

As an industry leader with over 50 years of experience providing the best vacuum pump solution for customers, DEKKER is an ISO 9001:2015 certified company that delivers superior products & service. Our custom engineered systems meet even the most demanding applications, from aeronautical to waste water & everything in between. Call DEKKER today with any questions or check out our helpful website!

More Vacuum Pump Manufacturers

Applications

A vacuum pump is necessary for a range of industrial settings and applications. These include: labs, surgical procedures, dental operations and a variety of manufacturing applications. Other applications include: ion implantation, dry etching, atomic layer deposition, electron microscopy, radiotherapy and radiosurgery.

In labs, vacuum pumps help to control delicate testing environments when contaminants could destroy experiments. During surgical procedures or dental operations, medical vacuum pumps provide suction to improve cleanliness and visibility. In terms of manufacturing, vacuum pumps are essential for vacuum forming, creating eye lenses, producing light bulbs and carrying out many other complex assembly steps that would be almost impossible without vacuum technology.

Some of the many industries in which vacuum pumps are important include: laboratory and research, healthcare and medicine, dentistry, industrial manufacturing, plastic molding, food processing, semiconductor and vacuum coating.

The History of Vacuum Pumps

Vacuum pumps have been around for quite some time. Originally, they were created just for use in demonstrations and research. When this was the case, they were made from glass and were about the size of a large glass jar. To make it work, users would coat its edges with liquid sealant, then place it upside down on a surface with an outlet. Then, they’d remove air via an air pump attached to the surface outlet.

The first true vacuum pumps were invented in the 1650s by Prussian engineer and physicist, Otto Von Guericke. His first vacuum pump invention was the air pump (1650), which he used to create partial vacuums. It was known to achieve much lower pressure levels than those pumps that came before it. In 1654, he demonstrated the efficacy of his vacuum pump during an experiment known today as the Magdeburg hemispheres experiment. During said experiment, he proved that not even two teams of horses could separate two hemispheres that he had joined together with a vacuum (evacuating the air). In the 1660s, Irish scientist Robert Boyle improved on Guericke’s model and used it to conduct experiments of vacuum properties. Then, British philosopher Robert Hooke helped Boyle develop an air pump that creates a vacuum.

After this, the scientific and engineering community lost interest in vacuum pumps for quite some time. It was not until 1855 that they returned to it. In 1855, Heinrich Geissler invented the mercury displacement pump, quickly leading to the invention of the vacuum tube. In 1865, German chemist Hermann Sprengel invented a vacuum pump (the Sprengel pump) that uses mercury drops, which fall through a small-bore capillary tube, in order to trap air that will be evacuated from the system. Later, Nikola Tesla created a device that contained a Sprengel pump, designed to create a high degree of exhaustion.

Vacuum pumps created during the 19th century were simple, low capacity fans that created small vacuums. Today, vacuum pumps, while based on these same models, are far more effective and efficient than their predecessors.

Design

Manufacturers usually make vacuum pumps from tough, corrosion resistant materials like stainless steel or titanium.

When designing and customizing a vacuum pump system, vacuum pump manufacturers consider a number of factors. These include: component materials, maximum and minimum vacuum level, maximum and minimum flow rate, pump size and pump speed. They make decisions on these details based on specifications such as: the type of liquid or gas to flow through the pump, the dimensions of the enclosed space in which the vacuum pump will go and the general nature of the application (how often it will be used, its required speed, its industry requirements, etc.)

To customize a vacuum pump system, manufacturers can do a lot of things, like using a unique number of pumps, or including chambers and seals, to create a higher or lower vacuum.

Features

Vacuum pumps typically consist of various components that work together to create and maintain a vacuum. The inlet port is where the pump draws in the gas or air from the chamber. This port is connected to the chamber through a sealed opening or connection. The gas then enters the pump and encounters the pump mechanism, which generates the necessary force to evacuate the gas.

The outlet or exhaust port, on the other hand, is where the pump expels the gas or air that has been evacuated from the chamber. This port is connected to a discharge system, which can include filters or condensers to remove any impurities or moisture from the exhaust gas.

Gasket seals, meanwhile, play a crucial role in maintaining the integrity of the vacuum system. They are used to seal the connections between the various components of the pump, ensuring that there are no leaks that would compromise the vacuum. Gasket seals are typically made from materials such as rubber or silicone, which have good sealing properties.

In addition to these components, vacuum pumps may also include other elements such as valves, gauges, and control mechanisms. Valves are used to control the flow of gas in the system, allowing for the regulation of pressure and the isolation of different chambers. Gauges provide measurements of the pressure within the system, allowing for monitoring and control. Control mechanisms, such as motors or electronic systems, regulate the operation of the pump and may include features like automatic shut-off or variable speed control.

All these components work together to create a functional vacuum pump. The pump draws gas from the chamber through the inlet port, and the pump mechanism generates the necessary force to evacuate the gas. The gas is then expelled through the outlet or exhaust port, passing through the discharge system if present. The gasket seals ensure that there are no leaks in the system, maintaining the vacuum integrity. Valves, gauges, and control mechanisms enable the operator to control and monitor the pump’s performance, adjusting parameters as needed. The coordinated operation of these components allows for the creation and maintenance of a vacuum within the desired pressure range.

Types

There are several types of vacuum pump systems. Essentially, every vacuum pump is an air pump because it moves air out of an enclosed space while also preventing it from re-entering that space.

There are three primary ways of directing airflow in a vacuum pump: positive displacement, momentum displacement, and entrapment. These three make up the most common types of pumps.

Positive Displacement Pump

Positive displacement pumps continuously open and exhaust a closed cavity in the system. Rotary vane pumps, scroll pumps, piston pumps, diaphragm pumps and liquid ring vacuum pumps can all be considered different types of positive displacement pumps. The positive displacement method is used in low-intensity vacuums.

Momentum Transfer Pump

Momentum transfer pumps remove the air from a sealed pump by propelling the air molecules through high-speed fans or gas jets. Examples of this technology include diffusion pumps and turbomolecular pumps. The momentum transfer principle is used to create low-pressure vacuums.

Entrapment Pump

Entrapment pumps trap gases. They do this by heating or cooling the gases so that they become much easier to catch. There are two main types of entrapment pumps: cryo and ion.

Cryo Pump

Cryo pumps use cold temperature surfaces called “arrays” to trap and freeze gases in a solid state.

Ion Pump

Ion pumps react with gases inside the pump chamber, then bury those gases in their wall. With ion pumps, customers can achieve ultra-high vacuum levels.

In addition, all vacuum pump systems are either wet or dry.

Wet Vacuum Pump

A wet vacuum system is any vacuum system that makes use of liquid at any point in the process. Wet vacuum pumps are able to achieve a lower vacuum pressure. The only downside is that wet vacuum pumps require much more maintenance and their failure could be very costly to industrial operations.

Wet vacuum systems may also use oil or lubricant as a sealant in order to create air-tight compression. If they use liquid within their mechanical enclosures to create airtight seals, they are known as liquid seal vacuums. If they use oil to provide the seals, they are known as oil-sealed vacuums. Oil-sealed vacuums are best in high-intensity situations because oil is an excellent seal between moving parts.

Dry Vacuum Pump

Dry systems are the opposite of wet systems; at no point do they use any liquid. Dry vacuum pumps eliminate the need for added oil, but they tend to be less effective in collecting contaminants and other particles. However, they do typically require less maintenance and are less likely to fail during critical applications. That’s why they are optimal in a completely different set of applications, such as aircraft instrumentation.

Finally, there are other vacuum pumps that feature the characteristics of more than one main pump type, or are unique to themselves.

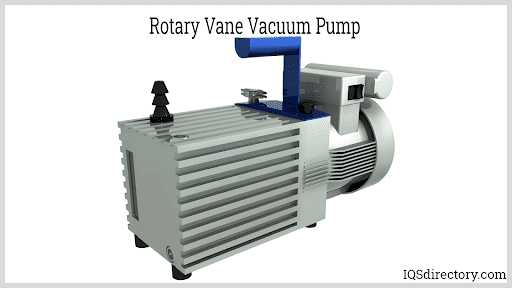

Rotary Vane Vacuum Pump

Rotary vane pumps are a type of oil sealed vacuum. These air-cooled, direct-drive pumps are used to pump dry, clean non-reactive gases. They are valued for their small carbon footprint and reliability.

Screw Air Compressor

Screw air compressors, also known as rotary-screw compressors, are gas compressors that work using positive displacement. Types include: piston vacuum pumps, diaphragm pumps and liquid ring vacuum pumps.

Piston Vacuum Pump

Piston vacuum pumps, or rotary piston vacuum pumps, are industrial vacuum pumps. They consist of rotating, varied-length pistons that pump fluids through check valves.

Diaphragm Pump

Diaphragm pumps pulsate to displace fluid, as check valves control the direction of fluid flow.

Liquid Ring Vacuum Pump

Liquid ring pumps are used to evacuate dry and wet gases, as well as condensable vapors and small liquid particles suspended in incoming gas.

Specialized Vacuum Pumps

There are a variety of specialized vacuum pump types, used for specific purposes. Examples include laboratory vacuum pumps, medical vacuum pumps, high vacuum pumps and automotive vacuum pumps.

Advantages of Vacuum Pumps

Vacuum pumps offer several advantages that make them a preferred choice in various applications. To begin with, vacuum pumps are known for their efficiency in evacuating gas from a chamber, creating and maintaining a vacuum. They can quickly remove gas molecules, achieving the desired pressure levels efficiently. This efficiency is particularly important in industries where rapid evacuation is necessary, such as in manufacturing processes or scientific experiments.

Additionally, vacuum pumps are designed to be durable and reliable. They are constructed with robust materials and engineered to withstand demanding operating conditions. Vacuum pumps undergo rigorous testing to ensure their durability and long service life. This makes them suitable for continuous operation and reduces the need for frequent maintenance or replacement.

Furthermore, vacuum pumps offer advantages over similar apparatus or techniques. One key advantage is their ability to achieve a higher level of evacuation. Vacuum pumps can reach lower pressures than other methods, allowing for a more complete removal of gas molecules from the chamber. This is especially advantageous in applications that require an extremely low-pressure environment, such as in semiconductor manufacturing or vacuum coating.

Moreover, vacuum pumps provide a controlled and predictable vacuum level. Their performance can be accurately regulated and adjusted, allowing for precise control over the pressure within the system. This is particularly beneficial in applications where maintaining specific pressure conditions is crucial, such as in vacuum drying or freeze drying processes.

In summary, vacuum pumps offer advantages in terms of efficiency, durability, and reliability. They are efficient in evacuating gas, ensuring rapid and effective removal. Vacuum pumps are built to be durable, withstanding demanding conditions and providing long-lasting service. Compared to other methods, vacuum pumps can achieve a higher level of evacuation and offer precise control over the vacuum level. These advantages make vacuum pumps a valuable tool in a wide range of industries and applications.

Accessories

There are several accessories available for vacuum pumps that can enhance their functionality and convenience. One such accessory is compressor kits, which are used to convert a vacuum pump into a vacuum and pressure pump. These kits allow the pump to generate positive pressure as well, expanding its applications. Meanwhile, vacuum gauge components are essential for accurately measuring and monitoring the pressure within the vacuum system. They provide real-time pressure readings, helping the operator ensure that the desired vacuum level is maintained. Extra safety valves are also crucial accessories that provide an additional layer of protection to prevent over-pressurization or damage to the pump. They act as pressure relief valves, releasing excess pressure if it exceeds the pump’s capacity. Additionally, vacuum hoses are flexible tubes used to connect the pump to the inlet or outlet ports, enabling the transfer of gas or air. They are available in various sizes and materials to suit different applications. Finally, power cord assemblies are essential accessories that provide the electrical connection between the pump and the power source. They ensure safe and reliable power supply to the pump. These accessories are important as they enhance the versatility, safety, and usability of the vacuum pump.

These accessories can be found through various sources. They are commonly available from vacuum pump manufacturers or distributors. Online marketplaces and industrial supply stores are also good places to search for these accessories. It is recommended to consult the pump manufacturer or supplier to ensure compatibility and quality of the accessories with the specific vacuum pump model. Additionally, specialized vacuum equipment suppliers may offer a wide range of accessories tailored to vacuum systems, providing a comprehensive selection to meet specific needs.

Proper Care for Vacuum Pumps

Proper care for your vacuum pump starts with familiarizing yourself with the issues commonly associated with your type of vacuum pump. Equipped with this knowledge, you will be better able to notice and remedy any potential problems early. This is a part of regular vacuum checkups, which you should perform per the recommendations of your supplier. In addition, if your system relies on lubricating oil, you need to make sure that it is never running low and that it never becomes contaminated.

Standards

Standards for vacuum pumps play a crucial role in ensuring the safety, reliability, and performance of these devices. These standards establish a set of guidelines and specifications that manufacturers must adhere to during the design, manufacturing, and testing of vacuum pumps. They provide a common framework for quality control, product compatibility, and interoperability. Standards help to enhance the overall consistency and reliability of vacuum pump systems, ensuring that they meet the desired performance criteria and can be used safely and effectively.

In the United States, several agencies and organizations are involved in the creation and development of standards for vacuum pumps. The American Society of Mechanical Engineers (ASME) has established codes and standards related to vacuum technology, such as the ASME B73.1 for rotary pumps. The International Organization for Standardization (ISO) is another important body that develops global standards for various industries, including vacuum pumps. ISO standards, such as ISO 21360-1 and ISO 21360-2, provide guidelines for performance testing and specifications for vacuum pumps.

These standards are important for several reasons. First, they promote uniformity and compatibility among different vacuum pump systems, allowing for easier integration and interchangeability of components. This is particularly valuable in industries that rely on vacuum technology, such as semiconductor manufacturing or pharmaceutical production. Additionally, standards provide a basis for quality assurance, ensuring that vacuum pumps meet specific requirements for performance, efficiency, and safety. Compliance with recognized standards gives confidence to users and purchasers that the products they acquire meet established industry norms. Moreover, these standards often incorporate the latest advancements and best practices, driving innovation and continuous improvement in vacuum pump technology.

Overall, standards for vacuum pumps are essential for establishing consistent performance, ensuring safety, and enabling compatibility across different systems. They are developed by organizations such as ASME and ISO to ensure that vacuum pumps meet the necessary quality and performance requirements. By adhering to these standards, manufacturers can provide reliable and efficient vacuum pump solutions, while users can confidently select and operate vacuum systems that meet industry-recognized specifications.

Choosing the Proper Vacuum Pump Manufacturer

To ensure you have the most productive outcome when purchasing vacuum pumps from a vacuum pump manufacturer, it is important to compare several companies using our directory of vacuum pump businesses. There, each vacuum pump manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each vacuum pump business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple vacuum pump businesses with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services