Oilless pumps are used in contexts in which accidental exposure to oil could damage products or endanger people. Medical vacuum pumps are often oilless to minimize patient and instrument exposure to oil. In the fabrication of hi-tech electronics, oilless pumps may also be necessary to avoid contaminating sensitive instruments with small amounts of oil. Read More…

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

GlobalVac & Air was founded in 1994 and is a leading supplier and packager of medical, lab and industrial vacuum systems. We specialize in rotary dry claw, liquid ring, rotary vane and rotary screw technology. Call us today for innovative solutions to all of your pumping needs!

In business since 1950, Osaka Vacuum is a manufacturer of highly reliable vacuum systems, industrial vacuum pumps, and vacuum pumping systems. Products include dry vacuum pumps, roots vacuum pumps, turbo molecular pumps, rotary vane vacuum pumps, liquid-ring vacuum pumps, oil-sealed vacuum pumps and more. Our motto is "reliable, long lasting products that give you safety and satisfaction.

As an industry leader with over 50 years of experience providing the best vacuum pump solution for customers, DEKKER is an ISO 9001:2015 certified company that delivers superior products & service. Our custom engineered systems meet even the most demanding applications, from aeronautical to waste water & everything in between. Call DEKKER today with any questions or check out our helpful website!

More Oilless Vacuum Pump Manufacturers

In industrial contexts, vacuum pumps are used for dry etching, solvent recovery, material handling, distilling, petrochemical processing, food manufacturing, finishing and many other processes. Oil-less dry pumps are generally less expensive than wet pumps because of lower initial investment and ongoing maintenance costs.

The cost of a dry vacuum pump failure can also be less than that of a wet pump failure, because oil or other liquid contamination of a vacuum enclosure can often be very damaging. However, oil allows for tighter seals between parts, which increases evacuation capacity. Because a dry vacuum pump cannot be sealed as well as an oil-sealed pump, their vacuum generation capacity is lower.

Dry vacuum pumps were developed in response to concerns about the threat that vacuum pump oil posed to people and the environment; historically vacuum pump oils have contained polychlorinated biphenyls, which have since been discovered to be toxic and carcinogenic.

Dry vacuum pumps avoid this problem and address concerns about pump reliability and maintenance. Dry pumps eliminate the need for contaminant disposal, which can be expensive. Because they do not require oil or fluid checks, maintenance costs are low.

Oilless vacuums vary in design but are often made of heavy-duty stainless steel because of the material's strength and resistance to contamination. Depending on the work environment and requirements, dry pumps can be equipped with vibration isolators and silencers. Some designs feature a cooling water jacket to counteract the high internal temperatures that result from the lack of an oil sealant.

Every oilless vacuum pump is a positive displacement pump, and each pump fits into one of three subcategories: rotary lobe, helical screw and claw. Each design uses two gear-synchronized rotors to trap and compress entering gases.

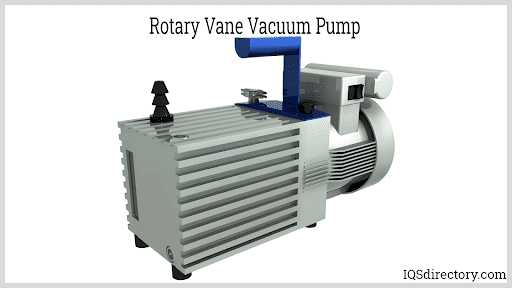

Rotary lobe vacuum pumps are similar to rotary vane pumps; two rolling rotors separate the chamber, compressing the gas and conveying it out. Helical screw pumps use two screw-like rotors whose threads fit together; gas becomes trapped between the flights of the screws, moved axially and is then discharged. Claw dry vacuum pumps use two claw-shaped rotors to compress the gas.

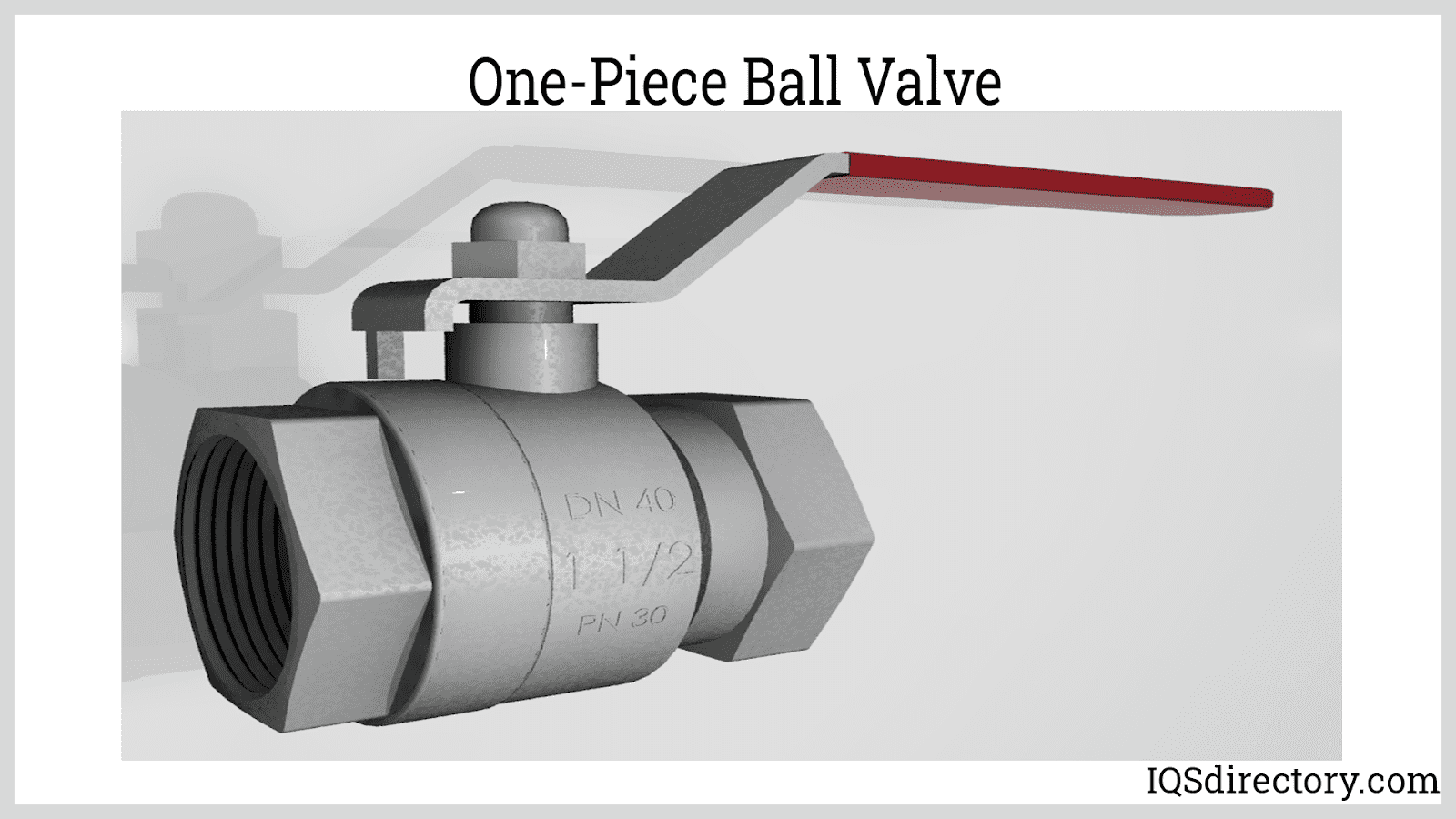

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services