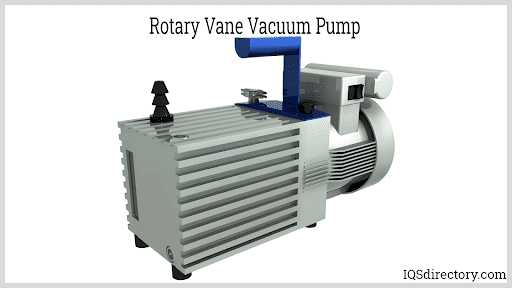

High vacuum pumps are used to remove gas molecules from a chamber. A vacuum pump lowers the pressure inside and creates a vacuum. High vacuum pumps are used when an extremely low final absolute pressure is needed. At atmospheric pressure, these pumps may constantly operate when linked to closed containers that need to be emptied, although they may only operate continuously for a short time. These pumps’ exhaust is not filtered. Hence fume cleaners with a specific design are available. The lubricated rotary vane and high vacuum pumps operate on the same principles. Read More…

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

GlobalVac & Air was founded in 1994 and is a leading supplier and packager of medical, lab and industrial vacuum systems. We specialize in rotary dry claw, liquid ring, rotary vane and rotary screw technology. Call us today for innovative solutions to all of your pumping needs!

In business since 1950, Osaka Vacuum is a manufacturer of highly reliable vacuum systems, industrial vacuum pumps, and vacuum pumping systems. Products include dry vacuum pumps, roots vacuum pumps, turbo molecular pumps, rotary vane vacuum pumps, liquid-ring vacuum pumps, oil-sealed vacuum pumps and more. Our motto is "reliable, long lasting products that give you safety and satisfaction.

As an industry leader with over 50 years of experience providing the best vacuum pump solution for customers, DEKKER is an ISO 9001:2015 certified company that delivers superior products & service. Our custom engineered systems meet even the most demanding applications, from aeronautical to waste water & everything in between. Call DEKKER today with any questions or check out our helpful website!

More High Vacuum Pump Manufacturers

In this instance, the stator is submerged in lubrication oil, which also serves as a sealant for air loss. These pumps are capable of greater pressures than any other rotary vane pump. A gas ballast system is included with these pumps to prevent the condensation of water vapor. High vacuum pumps can be constructed of two rotor-stator groups connected in series, with the first group drain connected to the second group’s intake system. They can be made of a single rotor-stator group (single stage) or two rotor-stator groups (dual stage).

How a High Vacuum Pump Works

The primary purpose of a vacuum pump is to modify the pressure inside a constrained area to physically or chemically produce a full or partial vacuum. Gas molecules will always move from high pressure to low pressure to fill the full area of that volume, attempting to equalize pressure across connected regions.

As a result, gas will naturally flow from a high-pressure area to the new area of low pressure until they are at equal pressure if a new low-pressure space is added. Remember that pushing molecules rather than "sucking" gases creates a vacuum. By switching between high and low-pressure states, vacuum pumps transport gas molecules from one area to another to create a vacuum.

Types of High Vacuum Pumps

Many different pump designs have been developed to produce high or ultra-high vacuums. One of these two operating principles, gas transfer or gas capture, is used by each type.

Molecular Drag Pumps and Turbo/Drag Pumps

These are hybrid vacuum pumps with similar design elements to both operating principles. These pumps combine the benefits of both types of pumps, notably the lower ultimate pressure of the turbo pump and the capacity for higher backing pressure of the drag pump. They do this by combining blades and ridged drums.

Turbomolecular Pumps

Molecular drag pumps use a rotor drum with a ridged surface and a cylindrical stator in place of a stator and rotor blades to provide gas molecules with a preferential motion and produce molecular flow through the pump. The name molecular "drag" pump refers to how gas molecules are physically dragged along the surface by this mechanism. These pumps can reach only 10-6 Torr as their maximum operating pressure. Therefore, these pumps are utilized for frequent cycle operations and applications with low conductance (pressure drop or resistance through the system).

Gas-Capture Pumps

Vacuum pumps that function on the gas-capture or gas-binding principle produce vacuums by physically engulfing gas molecules and retaining them in a frozen form. Compared to gas-transfer pumps, these pumps normally have fewer moving components, but they need to be periodically regenerated since they eventually become saturated with the material they are collecting.

Gas-Jet (Diffusion) Pumps

Gas-jet pumps, also known as diffusion pumps, use high-speed jets of diffusion vapor to sweep gas molecules out of the system and impart momentum. They are among the high vacuum pumps that are most frequently utilized. The extended service lives, lack of moving parts, and high reliability of diffusion pumps make them ideal.

Lighter gases like helium and hydrogen can be pumped at the fastest possible rate, thanks to them. Oil back streaming in oil diffusion pumps and process contamination are potential issues that can be mitigated by installing baffles and traps. Under the right circumstances, these pumps may achieve maximum vacuums of 10 Torr.

Compatibility of Materials

To avoid wear or corrosion and to guarantee a safe and hygienic operation, high vacuum pumps, as well as the lubricants and building materials used in their manufacture, must be compatible with the fluids they move or catch. In addition, since most pumps may pump various gases at various rates, the type, and consistency of gas being handled also affect the pump's performance. For instance, a cryopump will pump water vapor far more quickly than a turbomolecular pump of comparable size, but both pumps may pump nitrogen at the same speed.

Applications of High Vacuum Pumps

- They are used in laboratories for various research operations such as photolithography, electron microscopy, etc.

- They are used in vacuum coating glass, metals, and plastics. In addition, they are used for hard coating engine components on race cars.

- They are also used to assist with the mechanical drives in hybrid and diesel engines. In addition, they provide a power supply to the camshafts.

- They are used in the gas bottle filling and emptying application used in CRT, electric light, and bulbs for filling the bulb chambers with inert gases.

- They are also used in hydraulic brakes, cruise control systems, dampeners in the ventilation systems, and door lock mechanisms.

- They are employed in numerous processes, including freeze-drying, degassing, gel-drying, and others.

- Additionally, they are employed to support the mechanical drives in diesel and hybrid engines. Additionally, they supply camshafts with power.

- They can be applied to identify leaks.

Choosing the Right High Vacuum Pump Supplier

To make sure you have the most positive outcome when purchasing high vacuum pumps from a high vacuum pump supplier, it is important to compare at least 4 to 5 companies using our list of high vacuum pump suppliers. Each high vacuum pump supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each high vacuum pump business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple high vacuum pump businesses with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services