They are often made from stainless steel because of the material’s strength and contaminant-resistant properties. Read More…

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

GlobalVac & Air was founded in 1994 and is a leading supplier and packager of medical, lab and industrial vacuum systems. We specialize in rotary dry claw, liquid ring, rotary vane and rotary screw technology. Call us today for innovative solutions to all of your pumping needs!

In business since 1950, Osaka Vacuum is a manufacturer of highly reliable vacuum systems, industrial vacuum pumps, and vacuum pumping systems. Products include dry vacuum pumps, roots vacuum pumps, turbo molecular pumps, rotary vane vacuum pumps, liquid-ring vacuum pumps, oil-sealed vacuum pumps and more. Our motto is "reliable, long lasting products that give you safety and satisfaction.

As an industry leader with over 50 years of experience providing the best vacuum pump solution for customers, DEKKER is an ISO 9001:2015 certified company that delivers superior products & service. Our custom engineered systems meet even the most demanding applications, from aeronautical to waste water & everything in between. Call DEKKER today with any questions or check out our helpful website!

More Medical Vacuum Pump Manufacturers

These pumps may also be mounted on wheels or in cabinets so they can be easily moved when necessary.

Medical vacuum pump tubing and gaskets are made out of strong plastic and rubber that can withstand extreme conditions without boiling or releasing harmful gasses.

One of the most common uses for medical vacuum pumps is for the provision of suction during surgical procedures. Pneumatic air supply, gas chromatography, air quality samplers and analyzers rely on vacuum pumps as well. Simple vacuum pumps called aspirators remove excess fluids through a tube system. Aspirators are important vacuum pumps because they provide fast and easy suction almost anywhere.

Medical vacuum pumps vary in their configuration depending on a number of factors. Aspirators, for example, are basic, non-mechanical devices that generate a vacuum through the Venturi Effect, which is the reduction of pressure in an enclosure that occurs when a fluid flows through a constricted section of that enclosure (in this case a pipe or tube).

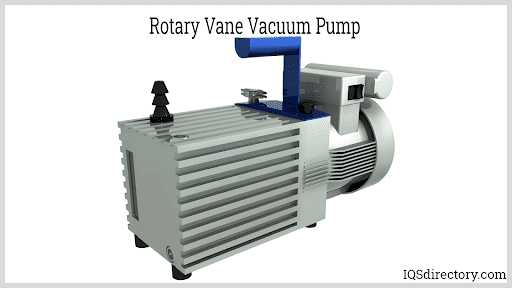

Other vacuum pumps can be more complicated. There are three main kinds of mechanical vacuum pumps: positive displacement, momentum transfer and entrapment pumps, though within those categories there are subcategories. Many medical vacuum pumps are positive displacement pumps that are also rotary vane pumps. Diaphragm pumps are another variety of positive displacement pump.

Momentum transfer pumps work by causing gas molecules to accelerate in a consistent direction through repeated collisions with a solid surface or steam jet. Entrapment pumps use rapid heating and cooling to cause condensation, which in turn traps molecules in a solid or absorbed state.

All vacuum pumps can also be identified as wet or dry. Oil-lubricated pumps and liquid ring vacuum pumps both involve a liquid at some point in their processes. Dry vacuum pumps don't make use of any liquid and are more suitable in healthcare contexts.

Lubricant oil could, if used in a medical vacuum pump, enter pump air streams and contaminate workspaces or harm patients. For this reason, almost every medical vacuum pump is oilless.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services