Venturi vacuum pumps are named after the Venturi effect. For the Venturi effect to occur, a gas or liquid must pass through an aspirator, also known as a tube. The cross-sectional area of this tube first narrows and then expands. As a result, the fluid’s pressure drops as the tube gets smaller. The fluid accelerates to maintain the continuity of its bulk. The Venturi effect thereby produces a vacuum at the tube’s narrowest point. Venturi vacuum pumps use this scientific method, which employs high-pressure air to generate a powerful vacuum. Read More…

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

GlobalVac & Air was founded in 1994 and is a leading supplier and packager of medical, lab and industrial vacuum systems. We specialize in rotary dry claw, liquid ring, rotary vane and rotary screw technology. Call us today for innovative solutions to all of your pumping needs!

In business since 1950, Osaka Vacuum is a manufacturer of highly reliable vacuum systems, industrial vacuum pumps, and vacuum pumping systems. Products include dry vacuum pumps, roots vacuum pumps, turbo molecular pumps, rotary vane vacuum pumps, liquid-ring vacuum pumps, oil-sealed vacuum pumps and more. Our motto is "reliable, long lasting products that give you safety and satisfaction.

As an industry leader with over 50 years of experience providing the best vacuum pump solution for customers, DEKKER is an ISO 9001:2015 certified company that delivers superior products & service. Our custom engineered systems meet even the most demanding applications, from aeronautical to waste water & everything in between. Call DEKKER today with any questions or check out our helpful website!

More Venturi Vacuum Pump Manufacturers

A Venturi vacuum pump produces suction using a tiny, disk-shaped nozzle. The pressure difference between ambient pressure and pressure in the nozzle creates a vacuum. This vacuum draws air through the nozzle and into the pump. Lowering the air pressure in the immediate area keeps debris out of the pump.

Compressed Air Venturi Pumps

The vacuum produced by a compressed air venturi system is produced using compressed air. A diffuser, a nozzle, and a compressor make up the system. The compressor pumps air into the nozzle, creating a high-velocity air jet. After hitting the diffuser, this air jet slows down and forms a low-pressure zone. The low-pressure area draws ambient air into the nozzle, and the resulting airflow produces the vacuum. The main benefit of adopting a compressed air venturi system over other pumps is it doesn’t require an electrical supply.

How Venturi Vacuum Pumps Work

The body of the venturi pump has an inlet, an outlet, and a nozzle in the middle. The flow of fluid is restricted by the nozzle, increasing its velocity while decreasing its pressure. Due to the vacuum produced by the pressure drop, fluid is drawn into the nozzle and then forced out on the other side.

Application of Venturi Vacuum Pumps

Venturi pumps are used in woodworking applications to make vacuum clamps to hold flat stock in place during routing or sawing. Venturi pumps are used for vacuum filtration when interacting with hazardous substances in laboratory work. Manufacturers may use Venturi pumps as hoists while assembling products because Venturi pumps can raise objects using suction cups. Venturi vacuum pumps are inexpensive to buy and run, and experts in many industries use them whenever possible.

Venturi Vacuum Pump Design

Venturi vacuum pumps offer a powerful and effective way to create a vacuum. They function by forcing air out of the pump through a small outlet port after forcing air into the pump through an inlet port. As a result, a fast-moving air jet is produced, sucking in the surrounding air and lowering the pressure inside the pump chamber. When a strong vacuum is necessary, such as when holding things in place during machining or sealing against air pressure, venturi pumps are frequently utilized. Manufacturers can also use them to transfer gases or liquids between containers.

Advantages of Venturi Vacuum Pumps

Although they need a compressed air source to operate, venturi vacuum pumps don't require electricity. As a result, these tiny, lightweight pumps can function for years without requiring maintenance or repairs. Additionally, since no heat is produced, they can continuously operate without overheating. The majority of Venturi vacuum pumps are built of aluminum. However, if they are designed for corrosive environments, they may be made of other metals, like stainless steel.

Choosing the Right Venturi Vacuum Pump Manufacturer

To make sure you have the most productive outcome when purchasing venturi vacuum pumps from a venturi vacuum pump manufacturer, it is important to compare at least 4 companies using our list of venturi vacuum pump manufacturers. Each venturi vacuum pump manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each venturi vacuum pump company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple venturi vacuum pump companies with the same quote.

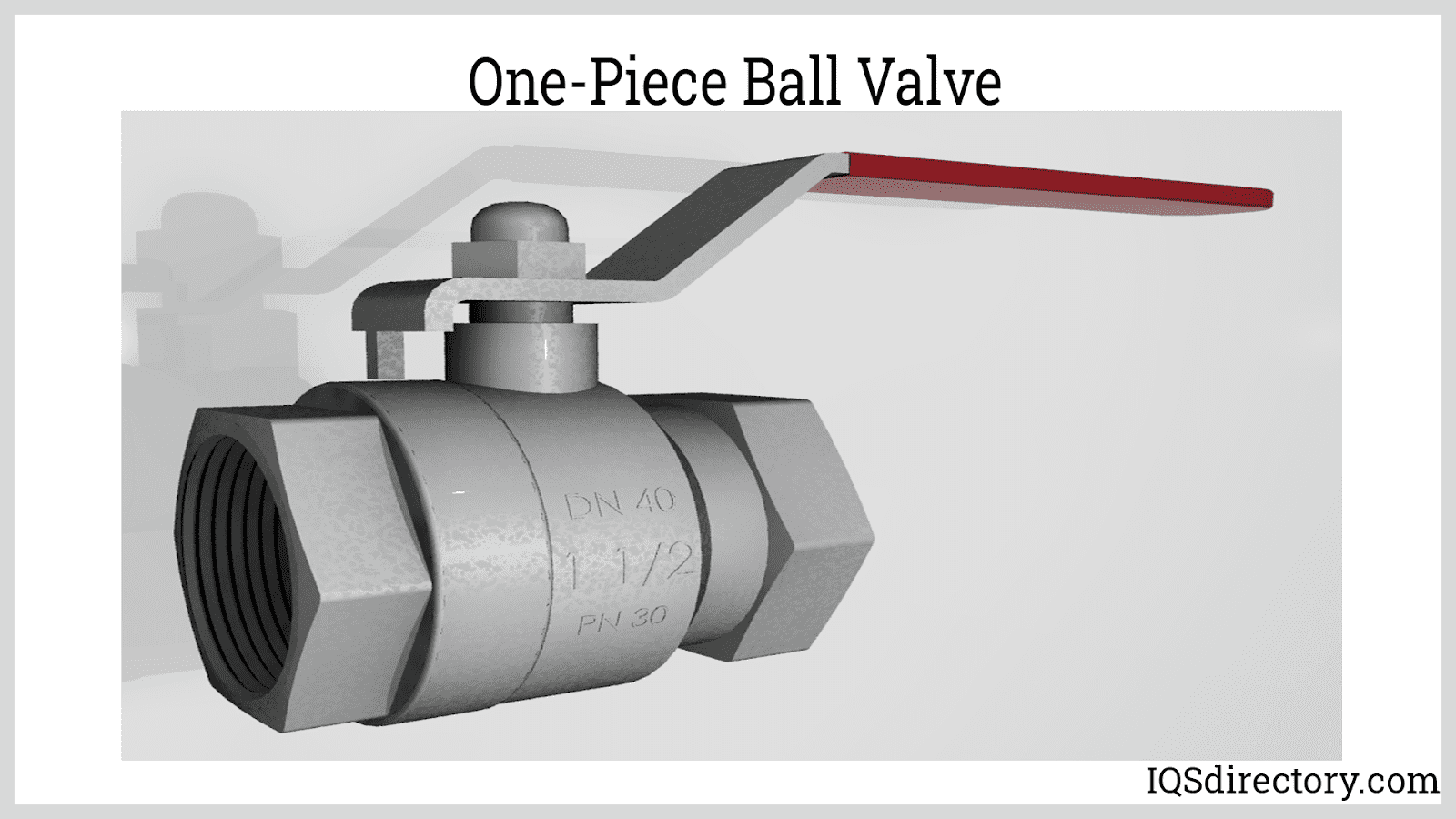

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

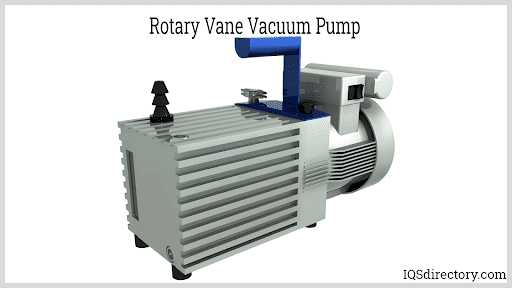

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services