Small vacuum pumps are smaller tools used to produce a vacuum inside sealed spaces. They are used for dental and medical purposes and are crucial in aviation because they enable airplane gyroscopic instrumentation to provide correct readings to pilots. Small vacuum pumps are typically constructed from sturdy and contamination-resistant materials like stainless steel or aluminum. Read More…

Gardner Denver provides vacuum pumps products such as rotary vane vacuum pumps, oilless vacuum pumps, linear and rotary piston pumps for a number of markets and applications. Provides excellent customer service to compliment their line of high-quality products.

MDC Vacuum Products manufactures vacuum components, including butterfly valves, vacuum gauges, and vacuum pumps. Our cryogenic sorption vacuum pumps are an economical roughing source, attaining up to 1x10-3 Torr vacuum level. Other features of our pumps include: clean vibration-free operation, heat regeneration, a positive pressure safety vent, no moving parts, and multiple pump capacity.

Here at US Vacuum Pumps, our broad range of industrial vacuum pumps cannot be topped. It is our dedication to our craft that makes us your premier choice for all of your vacuum pump needs. We will work with you in order to come up with a product that will fit your needs perfectly. All products are available for immediate shipment. To learn more, visit our website or send our qualified staff an...

We are a manufacturer of vacuum pumps, liquid ring vacuum pumps and rotary vane vacuum pumps. We provide custom-engineered, reliable vacuum pumps to meet all your needs. We also offer FloGard® RCP for monitoring the wear and tear on your vacuum pump to foresee problems before they happen.

More Small Vacuum Pump Manufacturers

Types of Small Vacuum Pumps

Like all other types of vacuum pumps, manufacturers can set up small ones using one of three configurations: positive displacement, momentum transfer, or entrapment.

Positive Displacement in Small Vacuum Pumps

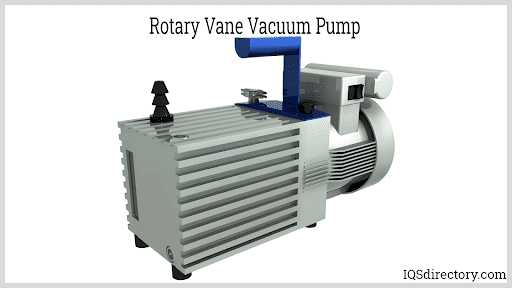

Positive displacement operates under the premise a vacuum can be partially created by increasing a container's volume. By constantly closing off, exhausting, and re-expanding one of their compartments, positive displacement vacuum pumps can continuously empty chambers without requiring infinite growth. Diaphragm pumps, rotary vane pumps, piston pumps, screw pumps, external vane pumps, toepler pumps, and lobe pumps are a few examples of tiny positive displacement pumps.

Momentum Transfer in Small Vacuum Pumps

Momentum transfer in small vacuum pumps drives gathered gas molecules to accelerate in one direction. They accomplish this by repeatedly slamming onto a hard surface or a steam jet. Turbomolecular pumps and diffusion pumps are two types of tiny momentum transfer pumps.

Entrapment in Small Vacuum Pumps

Tiny vacuum pumps designed for entrapment work will rapidly cool and heat to produce condensation. This will compress and trap gas molecules in either an absorbing or solid form. Ion pumps, cryopumps, sorption pumps, non-reactive getter pumps, and titanium sublimation pumps are a few examples of small entrapment pumps.

Oilless Vacuum Pump

Small vacuum pumps can be made wet, dry, or oilless. Oil or other liquids must seal and lubricate inside wet vacuum pumps. Oilless vacuum pumps are used in situations where precise control is needed. Oilless pumps do not produce as strong of a seal as those that utilize oil or another liquid. Thus they take less time and money to clean. Wet pumps also produce lower enclosure pressures than dry vacuum pumps. However, they are expensive because they require equipment to prevent oil backstreaming.

Liquid Ring Pumps

Liquid ring pumps can be used as gas compressors and vacuum pumps. In a liquid-ring pump, a spinning ring of liquid is stirred to create the compression-chamber seal. The rotor is the only moving component, making them low-friction designs. The shaft seals are the only points of sliding friction. An induction motor is used to power liquid-ring pumps.

Applications of small vacuum pumps

Small vacuum pumps can be portable and used as emergency supplies in high-risk locations like nursing homes, public swimming pools, and ambulances. Additionally, they provide suction for use during surgical and dental operations. Portable pumps frequently have an extra layer of metal or plastic on top for visual appeal.

Miniature vacuum pumps are available for even smaller applications when a battery-powered device is needed. In several fields of science and research, they are used for complex, delicate applications like particle counting and particle sizing. Small vacuum pumps can be tucked away into workspace areas that won't obstruct operations. Some have housings that are created expressly to fit in small locations.

Choosing the Proper Small Vacuum Pump Manufacturer

To make sure you have the most productive outcome when purchasing small vacuum pumps from a small vacuum pump manufacturer, it is important to compare at least 4 manufacturers using our small vacuum pump directory. Each small vacuum pump manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each small vacuum pump business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple small vacuum pump businesses with the same message.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services