An industrial vacuum pump is a mechanical tool used to remove gases or liquids from the inside of tubes, containers, or any other system when it is necessary to lower the internal pressure below atmospheric levels. Systems for industrial vacuum pumps are created for usage in several sectors, including the manufacturing, semiconductor, and food and beverage sectors. These systems are often made to last and see heavy industrial use. Read More…

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

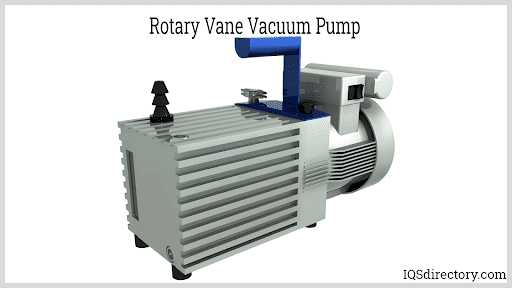

GlobalVac & Air was founded in 1994 and is a leading supplier and packager of medical, lab and industrial vacuum systems. We specialize in rotary dry claw, liquid ring, rotary vane and rotary screw technology. Call us today for innovative solutions to all of your pumping needs!

In business since 1950, Osaka Vacuum is a manufacturer of highly reliable vacuum systems, industrial vacuum pumps, and vacuum pumping systems. Products include dry vacuum pumps, roots vacuum pumps, turbo molecular pumps, rotary vane vacuum pumps, liquid-ring vacuum pumps, oil-sealed vacuum pumps and more. Our motto is "reliable, long lasting products that give you safety and satisfaction.

As an industry leader with over 50 years of experience providing the best vacuum pump solution for customers, DEKKER is an ISO 9001:2015 certified company that delivers superior products & service. Our custom engineered systems meet even the most demanding applications, from aeronautical to waste water & everything in between. Call DEKKER today with any questions or check out our helpful website!

More Industrial Vacuum Pump Manufacturers

Industrial Vacuum Pump’s Operating Principle

No matter the technology, the fundamental principles of an industrial vacuum pump remain the same. Air molecules (and other gases) are removed from the vacuum chamber by vacuum pumps (or the outlet side in the case of a higher vacuum pump connected in series). Additional molecules become more difficult to remove as the chamber's pressure is decreased.

An industrial vacuum system (Fig. 1) must function throughout a portion of an extremely wide pressure range, typically from 1 to 10-6 Torr / 1.3 to 13.3 mar of pressure. This range is extended to 10-9 Torr or below in research and scientific applications. A typical vacuum system uses a variety of pumps, each of which operates in series sometimes and covers a fraction of the pressure range, to achieve this.

Industrial Vacuum Pump Types

Axial-Flow Vacuum Pumps

The ability of centrifugal pumps to deliver energy to fluids—particularly liquids—through the action of a field of centrifugal forces distinguishes them from other hydraulically powered equipment. Their primary function is to move fluids by raising the pressure. Centrifugal pumps come in various shapes, but their fundamental principles and fluid dynamics are always the same.

Liquid Ring Vacuum Pumps

In contrast to rotary vane pumps, which use vanes to stir a spinning ring of liquid to create the compression-chamber seal, liquid ring vacuum pumps use rotating rings of liquid instead of vanes. The rotor is the only moving component, making them, by nature, low-friction designs. The shaft seals are the only points of sliding friction.

Rotary Claw Vacuum Pumps

Rotary claw vacuum pumps efficiently and affordably produce a contact-free vacuum. This efficiency is made possible by the rotary claw design's internal compression principle. The static compression method serves as the foundation for claw vacuum pumps. Internal volume contraction causes compression, as opposed to rotational lobes. A claw pump has two rotors in it. They observe extremely small clearances as they rotate in opposing directions inside a compressor housing without making touch. They are coordinated by a gear.

Side-Channel Blowers

Side channel blowers feature an impeller positioned directly on the motor shaft for contact-free compression. Through the inlet, the gas is ingested. When entering the side channel, the revolving impeller gives the gas velocity in the rotational direction. The gas is accelerated outward, and the pressure rises due to centrifugal force in the impeller blades. Every spin adds kinetic energy, causing the pressure along the side channel to rise even more. The side channel narrows near the rotor, clearing the gas from the impeller blades and letting it escape the pump through the output silencer.

Industrial Vacuum Equipment Benefits

Using industrial vacuum equipment has various benefits. Some of the most important advantages are listed below.

Capabilities for Customization

One of the key benefits of industrial vacuums is their ability to be tailored by the manufacturers to suit a company's unique requirements and surroundings. This customization implies that the company receives a system specially created to satisfy their particular requirements.

Longevity and Robustness

The fact that industrial vacuums are built to last is another significant benefit. These systems can sustain years of usage because they are made for heavy-duty applications. As a result, the system will be replaced less frequently, which will end up saving money.

The Simplicity of Use and Upkeep

Industrial vacuums are simple to use and require little upkeep. As a result, employers will only have to devote a little effort to training staff members to use the system. Also, maintaining the system will cost little money or time. There will be detailed operating instructions included with the vacuum system. Be careful to work only with reputed suppliers with top-notch industrial vacuum pump equipment. So that the company can concentrate on finishing the task at hand, a good industrial vacuum pump manufacturer can guide a purchaser through all the pumps and help select the exact one needed to suit a specific purpose.

Applications of Industrial Vacuum Pumps

The Food Business

Industrial vacuum pumps are used for lyophilization, degassing, and drying. In this scenario, the pumps are specifically suggested to evacuate drying chambers used for food freeze-drying systems, achieving the necessary vacuum levels for concentration and solvent separation. The pump's chemical resistance and concentration tolerance must be sufficient for vacuum-based concentration. Additionally, while the process is running, the equipment can separate solvents.

The Electrical Sector

This equipment is designed to work with high-voltage electrical elements. As an illustration, transformers and coils can evaporate moisture to lessen the amount of humidity and other contaminants.

Curing Resins and Varnishes

Vacuum systems can handle the degassing of varnishes, resins, and silicon before the start of the curing process, leaving air bubbles trapped. This degassing includes polyurethane, the resin that cures the fastest.

Pharmaceutical Companies

Degassing and drying are essential steps in the pharmaceutical products' finishing process. Degassing is followed by drying. Humidity is removed from a solid element throughout this process with external heat. In addition, freeze drying, also known as lyophilization, is a common method for removing water from physical goods without causing harm to them. For example, a vacuum pump is utilized while packing pharmaceutical medicines to remove air from the container. Proper packing ensures the products are transported safely and reach the customer aseptically.

The Toy Business

Vacuums are essential to several toy coating procedures that use steam to apply plastic, glass, or metal. With sufficient vacuum technology, these processes are typically possible. In addition, vacuum degassing systems make metals denser through the process of degassing. This process also helps to ensure that the machining process is carried out as effectively as possible by preventing the emergence of porous zones and hard spots.

Optical Technology

In the optical sector, thin active layers are deposited using vacuum equipment. Thin layers of plastic or architectural glass can be applied to diamonds to provide dry operations that are more effective.

Choosing the Correct Industrial Vacuum Pump Company

To make sure you have the most beneficial outcome when purchasing industrial vacuum pumps from an industrial vacuum pump company, it is important to compare at least 4 companies using our industrial vacuum pump directory. Each industrial vacuum pump company has a business profile page that highlights their areas of experience and capabilities and a contact form to communicate with the company for more information or request a quote. Review each industrial vacuum pump business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple industrial vacuum pump companies with the same quote.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services