Dry vacuum pumps have an oil- and liquid-free sealing system and are non-contact. They achieve a clean vacuum without any oil or water back-flow or diffusion. These pumps are simple because they don’t need routine maintenance like replacing or replenishing water or oil. Read More…

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

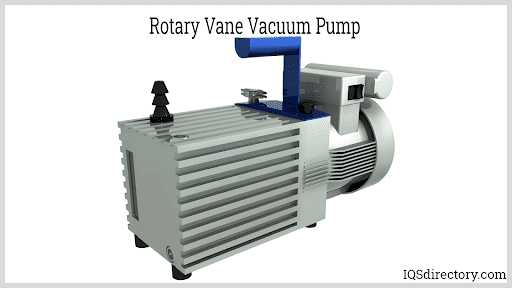

GlobalVac & Air was founded in 1994 and is a leading supplier and packager of medical, lab and industrial vacuum systems. We specialize in rotary dry claw, liquid ring, rotary vane and rotary screw technology. Call us today for innovative solutions to all of your pumping needs!

In business since 1950, Osaka Vacuum is a manufacturer of highly reliable vacuum systems, industrial vacuum pumps, and vacuum pumping systems. Products include dry vacuum pumps, roots vacuum pumps, turbo molecular pumps, rotary vane vacuum pumps, liquid-ring vacuum pumps, oil-sealed vacuum pumps and more. Our motto is "reliable, long lasting products that give you safety and satisfaction.

As an industry leader with over 50 years of experience providing the best vacuum pump solution for customers, DEKKER is an ISO 9001:2015 certified company that delivers superior products & service. Our custom engineered systems meet even the most demanding applications, from aeronautical to waste water & everything in between. Call DEKKER today with any questions or check out our helpful website!

More Dry Vacuum Pump Manufacturers

How They Function

Two parallel, non-contacting, helical screw-shaped rotors rotate synchronously at high speeds using precise gears to form a dry screw vacuum pump. They revolve counterclockwise. Consequently, the amount of gas at the input is trapped. Afterward, it is moved into the exhaust duct and toward the exhaust port. The compression chambers or pockets that convey the gas are created by the stator's walls and the unique design of the intermeshing screws.

Two screw rotors rotate in opposition to one another inside dry screw vacuum pumps. Between the chambers of the cylinder and the screw, the pumped medium is imprisoned. It is compressed there before being delivered to the outlet. The cylinder or the screw rotors are not in contact with one another or each other during this operation. Water or air conditioning can be used to achieve cooling.

Vacuum Pump Types

Pumps for Chemical Duty Dry Vacuum

Solvents can condense and be recovered on the vacuum pump's discharge side. This design creates a good solvent recovery option. Depending on the design, all chemical duty dry pumps may achieve vacuum values of 5 to .05 Torr. Compared to other technologies, these benefits come at a very high cost. Screw, multi-lobe, and claw are the three main chemical-duty dry vacuum pump varieties.

Vacuum Dry Claw Pumps

All manufacturers claim their dry pumps can handle corrosive vapors. There is no natural internal flushing of the process out of dry vacuum pumps because they are "dry." By preventing them from condensing and retaining them as vapors, corrosives are "managed." More caution must be used when handling corrosives, using start-up and shut-down purge cycles, and protecting the pump from process disruptions.

It is claimed that the coatings on screw-type dry vacuum pumps provide corrosion resistance. For some manufacturers, this offers minimal protection, as the coating is more of a manufacturing wear coating than a "pin-hole free" coating. With a PFA or other Teflon-type coating, you can be more certain that the coating is not worn and will hold up better for the cooler working dry pumps (350°F and less).

Some dry pumps can operate HOT, some even exceeding 500°F. As a result, some solvents' potential auto-ignition risks pose a serious risk to public safety. Additionally, due to their high operating temperatures, close-running components may accumulate polymerization of process gases. This polymerization leads to maintenance issues or wears coating removal. Since most of these dry pumps use an air bleed to cool the revolving claws or screws, which end up being the hottest section of the pump, even cold operating dry pumps might experience polymerization.

Dry Screw Vacuum, Horizontal

Two screw rotors inside a cylinder make up dry screw vacuum pumps. As a result, the gas is transferred to the discharge after becoming stuck between the cylinder and screw chambers. Very small clearances are kept between the screws to create a vacuum. If the substance is sticky, however, the screw tips may rub against the bore surface and produce heat, which may finally result in a seizure. This technique is somewhat more sensitive to temperature changes; upon heating, the rotors expand more quickly than the shell, resulting in seizures. In addition, the entire pair of screws must be replaced even when just one of the screws is damaged.

The rotors (screws) have coatings made of PEEK and PFA on them. The coating may become damaged if there is any condensation inside the pump, if particles enter, or if a seizure is brought on by excessive heat. Since recoating screws is expensive, handling this equipment should be done with extreme caution. Since recoating cannot be done on-site, the vendor must receive the equipment, which can result in a month-long period of downtime. Low boilers with appropriately set process parameters can use this technology. However, maintenance for this kind of pump can be quite costly for large boilers and changing process parameters.

Vacuum Pump With Vertical Reverse Claw/Claw and Lobe

With claw vacuum pumps, two claw-shaped rotors inside the housing rotate in the opposing direction. The air or gas is compressed and released after being sucked in by the claw rotors—a deeper root stage aids in providing a better vacuum.

Compared to horizontal designs, which are more susceptible to condensation and corrosion, vertical designs provide naturally free draining and have lesser odds of condensation occurring inside pumps. In addition, the rotors' (lobe and claw) surfaces are uncoated. This design can better handle sticky material and resist temperature changes in the inlet gas without endangering the pump's internal components.

Why Choose Dry Vacuum Pumps?

Dry vacuum pumps are the solution for limiting the environmental footprint while assisting businesses in increasing productivity with better quality and through a faster vacuum pump. Solvent recovery, distillation, evaporation, crystallization, deodorization, and filtration are just a few of the many processes used by a dry vacuum pump. In addition, dry vacuum pumps are non-polluting; no smell or oil is released. In addition, dry vacuum pumps are silent and vibration-free. They are portable and lightweight, making them ideal for various laboratory tasks.

How to Select a Vacuum Pump

When selecting a vacuum pump, several considerations must be made. To begin with, one should consider the quality and desired vacuum level. A rough or low vacuum, a high vacuum, and an ultrahigh vacuum are the three different forms of vacuum. The number of molecules per cubic centimeter declines as pressure falls. Vacuum quality thus improves.

The Uses of Dry Vacuum Pumps

Dry vacuum pumps have many applications, including desiccators, furnaces, vacuum ovens, liquid and air filtration, and more.

Choosing the Proper Dry Vacuum Pump Manufacturer

To make sure you have the most productive outcome when purchasing a dry vacuum pump from a dry vacuum pump manufacturer, it is important to compare at least 5 manufacturers using our dry vacuum pump directory. Each dry vacuum pump manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each dry vacuum pump company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple dry vacuum pump companies with the same quote.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services