There are two different types of vac pumps: electromechanical pumps and compressed air pumps. The type of vac pump that you require is dependent on your type of application and the requirements that come along with your application. Read More…

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

GlobalVac & Air was founded in 1994 and is a leading supplier and packager of medical, lab and industrial vacuum systems. We specialize in rotary dry claw, liquid ring, rotary vane and rotary screw technology. Call us today for innovative solutions to all of your pumping needs!

In business since 1950, Osaka Vacuum is a manufacturer of highly reliable vacuum systems, industrial vacuum pumps, and vacuum pumping systems. Products include dry vacuum pumps, roots vacuum pumps, turbo molecular pumps, rotary vane vacuum pumps, liquid-ring vacuum pumps, oil-sealed vacuum pumps and more. Our motto is "reliable, long lasting products that give you safety and satisfaction.

As an industry leader with over 50 years of experience providing the best vacuum pump solution for customers, DEKKER is an ISO 9001:2015 certified company that delivers superior products & service. Our custom engineered systems meet even the most demanding applications, from aeronautical to waste water & everything in between. Call DEKKER today with any questions or check out our helpful website!

More Vac Pump Manufacturers

If you are unsure of what type of vacuum pump is best for you and your application, consulting a knowledgeable vac pump specialist or manufacture is the best step to take to get the product that you need. Vac pumps are found in a number of different applications from vehicles to microwaves, each type of vac pumps has its own set of pros and cons.

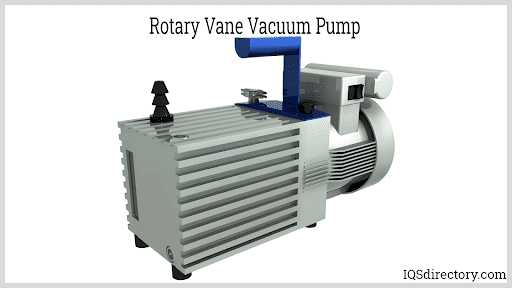

First, let's look at the electromechanical pump. This form of vac pump utilizes a rotating rotor and vanes which are used to trap air and force it through the pump which creates a partial vacuum behind it.

This type of vac pump requires a source of electricity as it often has an electric motor to give power for the rotor to rotate. For this reason and others, this type of vac pump is only used when certain conditions are met which means that it is often used in less critical situations.

A compressed air pump on the other hand works by forcing air through a nozzle. This creates a vacuum when it interacts with the high pressure of the outside air. These types of vac pumps are used in the manufacturing world in order to move different products and to keep machines from being damaged while providing them power.

Today, you can find vac pumps in all kinds of applications from the power brakes and cruise control in your car to the processing of semiconductors.

Whatever your application may be, working with the right vac pump manufacturer is the best way to ensure that you receive a vacuum pump that is designed with your type of application in mind. The right vac pump manufacturer will be able to tell you what type of vac pump is right for you and your application.

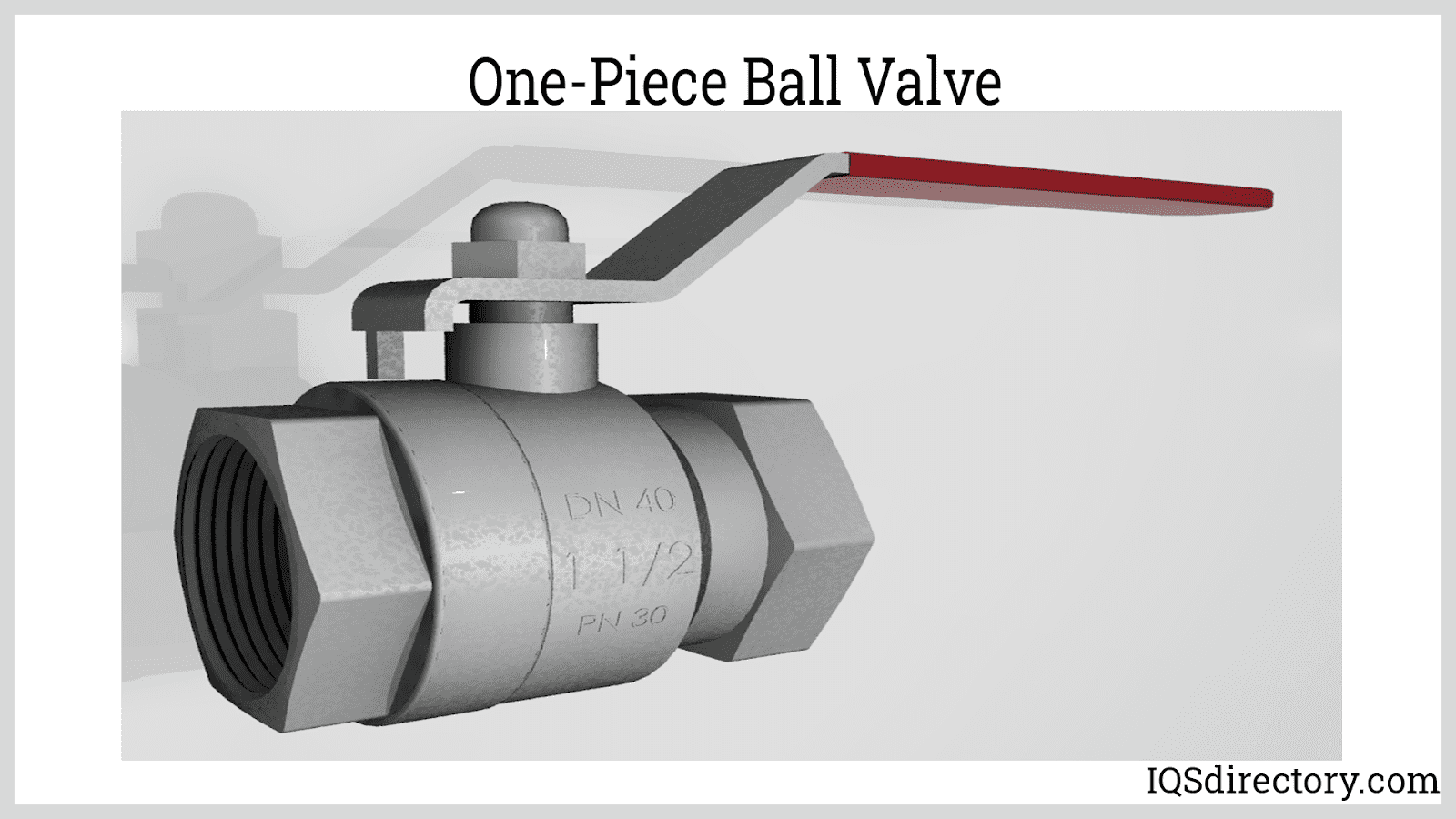

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services