In its most basic form, a rotary vane vacuum pump is a pump technology that allows air to be compressed inside the pump chamber to create suction. This suction removes air molecules from a vessel or area. Rotary vane vacuum pumps operate based on the positive displacement pumping theory. They are designed with a rotor positioned inside a cylindrical housing or stator. Due to centrifugal force, blades positioned inside the rotor rotate in and out while adhering to the interior surface of the housing. Read More…

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

GlobalVac & Air was founded in 1994 and is a leading supplier and packager of medical, lab and industrial vacuum systems. We specialize in rotary dry claw, liquid ring, rotary vane and rotary screw technology. Call us today for innovative solutions to all of your pumping needs!

In business since 1950, Osaka Vacuum is a manufacturer of highly reliable vacuum systems, industrial vacuum pumps, and vacuum pumping systems. Products include dry vacuum pumps, roots vacuum pumps, turbo molecular pumps, rotary vane vacuum pumps, liquid-ring vacuum pumps, oil-sealed vacuum pumps and more. Our motto is "reliable, long lasting products that give you safety and satisfaction.

As an industry leader with over 50 years of experience providing the best vacuum pump solution for customers, DEKKER is an ISO 9001:2015 certified company that delivers superior products & service. Our custom engineered systems meet even the most demanding applications, from aeronautical to waste water & everything in between. Call DEKKER today with any questions or check out our helpful website!

More Rotary Vane Vacuum Pump Manufacturers

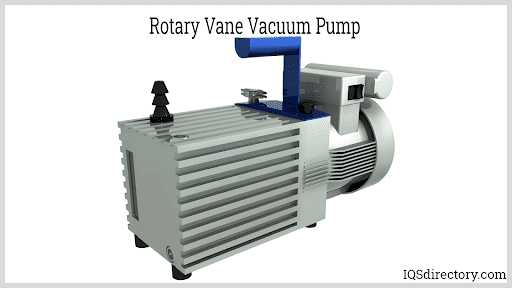

Design of Rotary Vane Vacuum Pump

Rotary vane vacuum pumps function using positive displacement. This means they create a vacuum and continuously evacuate chambers without needing to expand indefinitely by cutting off, exhausting, and re-expanding one of their sections. Positive displacement rotary vane pumps can also be built as dry or oil-sealed pumps. Dry pumps don't use any liquid to function.

Dry pumps rely on internal dimensional accuracy to create a vacuum, while wet pumps use fluid to form a seal. Oil-sealed pumps are wet pumps that specifically use oil to form a seal. Furthermore, a direct drive is used to construct many rotary vane vacuum pumps. Each rotary vane vacuum pump is constructed utilizing the same fundamental parts.

Depending on the design, size, or model, there will be modifications to the components. However, the below parts are typical of oil-lubricated and dry-running pumps.

Rotor: The pump’s rotor is usually wound with copper. The rotor rotates in this electrical engine and needs energy. The spiral layout's stationary element is called the stator. It encircles the internal surfaces of the motor housing and carries electrical current.

Vanes and Blades: The vanes are large blades affixed to a revolving axis or wheel. The vanes form a seal with the wall of the pumping chamber to stop fluid from flowing back across the pump.

Oil Sump: The oil sump stores the engine oil needed for sealing. An oil pump will send oil out of the sump, through the oil filter, and into the engine block's oil channels. The sealing points are then used to restore the oil to the oil sump.

Suction Flange: A suction tube is attached to a hydraulic tank using suction flanges. They create a seal to stop fluid leaks and pollution from getting into the tank. The suction element is also made possible via flanges without draining the tank.

Cylindrical Housing: The housing covering the pump’s exterior is usually made of aluminum die-casting. The compressor is housed inside.

Motor: A device that transforms electrical energy (AC or DC) into mechanical energy is an electric motor. The motor's magnetic field and the electric current flowing through a wire winding interact to produce the torque applied to the motor shaft.

Float Valve: A float detects changes in elevation on an oil-free surface and reacts by opening or closing a valve.

Applications of Rotary Vane Vacuum Pumps

Oil-Lubricated Rotary Vane Vacuum Pump Applications

- These pumps are used in chemical and pharmaceutical processes, including degassing, crystallization, drying, distillation, evaporation, supercooling, fractionation, impregnation, vacuum coating (sublimation), and vacuum filtering.

- Centralized vacuum systems are used in the food & beverage packaging sector in bottling and filling machinery.

- Examples of industrial applications include vacuum hold-down, dust extraction systems, drying systems, and industrial furnaces.

- Oil-lubricated vane pumps are used in pneumatic transport

Dry Running Rotary Vane Vacuum Pump Applications

- Aeration in environmental engineering.

- Industrial applications include picking and placing and lifting and holding.

- Machines used in the packaging sector.

- Dry-running rotary vane vacuum pumps may be used in post-press and printing presses in the printing business.

- Industry of woodworking - vacuum hold down.

Advantages of Rotary Vacuum Pumps

One of the most common vacuum pump is the rotary vane vacuum pump. In actuality, most vacuum pumps use rotating vanes, paddles, blades, or impellers to move shuttle gas into and out of an enclosure. Therefore, any vacuum pump using any of these parts is a rotary vacuum pump.

Choosing the Right Rotary Vane Vacuum Pump Supplier

To make sure you have the most productive outcome when purchasing a rotary vane vacuum pump from a rotary vane vacuum pump supplier, it is important to compare at least 4 suppliers using our rotary vane vacuum pump directory. Each rotary vane vacuum pump supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each rotary vane vacuum pump company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple rotary vane vacuum pump companies with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services